Sales Executive Yanis:

Tel:+8613872882788 E-mail:[email protected]

Name of vehicle |

Chemical tanker truck |

Vehicle type |

FW5250GFWZ |

Chassis type |

CA1260PK2L5T3BE6A81 |

Volume |

8-20cubic meters |

Total mass |

25000Kg |

Quality of equipment (Kg) |

9705Kg |

Vehicle length |

10730 ×2550×3650 |

Rated load mass (kg) |

15600 |

The engine |

CA6DH1-26E61 260 horsepower |

Chassis configuration |

Haworth TX5; Special Purpose Vehicle; TX-K Cab; Main Airbag+Sub Easy Seat; MC07.25-60 Engine; HW95508STC Transmission+HW45ZC Flange Pickup; VPD75D Front Axle (Disc); MCY11BES Single Rear Axle (Disc); Speed Ratio 4.63; Dual Deck Frame (8+4/280); Front and Rear Air Suspension (3/3/-); 8198 Steering Wheel; Front Exhaust System; EBS+ESC; Centre Bumper (Non-metallic); Aluminium Wheels (Domestic); 295/3/-; EBS+ESC; Medium Bumper (Non-metallic); Aluminium Wheels (Domestic) -); 8198 steering gear; front exhaust system; EBS+ESC; centre bumper (non-metallic); aluminium alloy wheels (domestic); 295/80R22.5; hand-electric electric lift; 300L fuel tank; LDWS+FCWS (with radar); knob PTO; China National Heavy Duty Truck Intelligent Pass D version; electromagnetic power switch; steering wheel flat tyre emergency device; 165AH battery; optional tyre pressure monitoring system; |

tanker configuration |

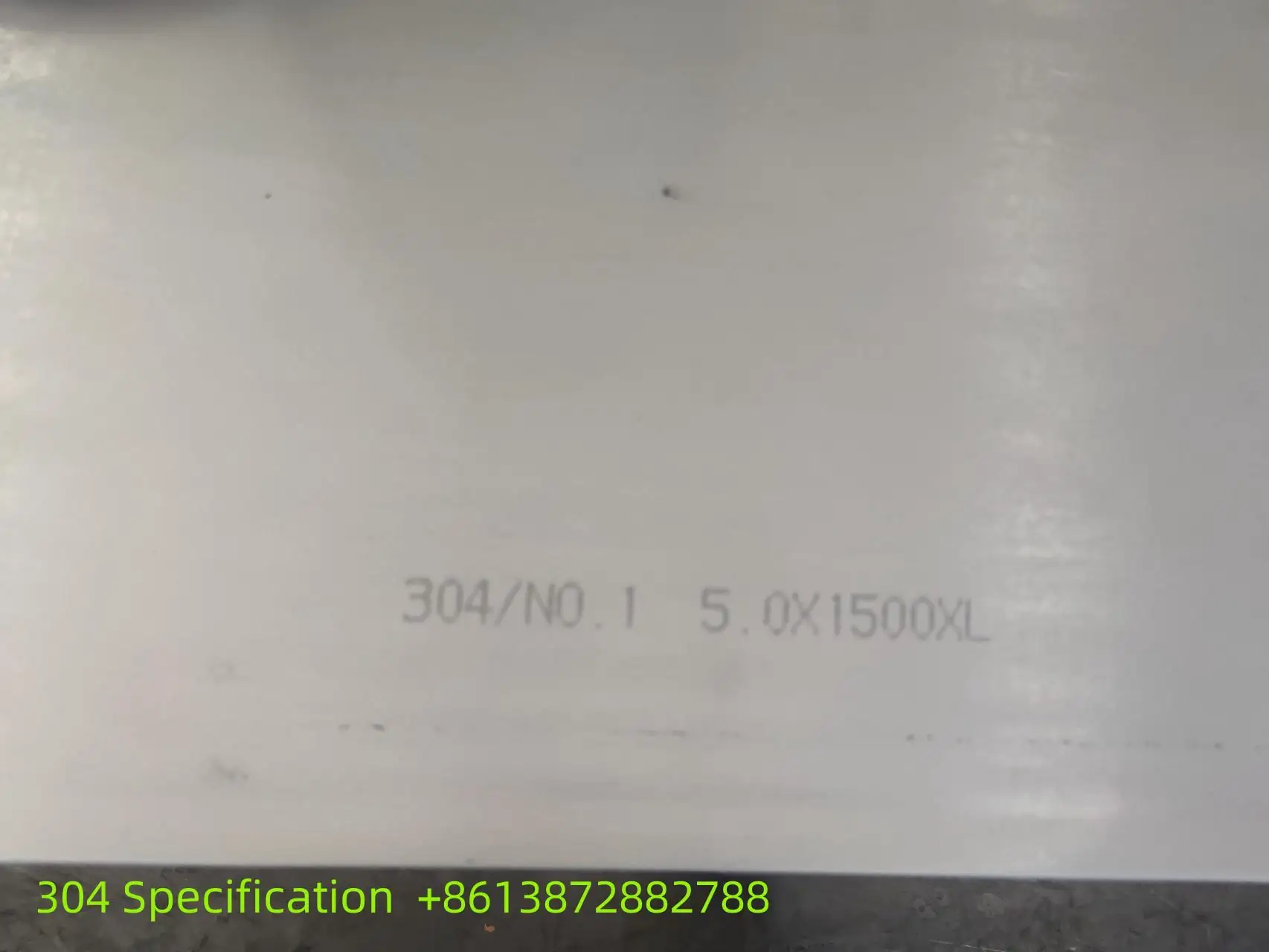

Upper standard configuration (stainless steel, carbon steel): in line with GB18564.1-2019 standard; L4BH design code; round tank; SUS304, SUS316 or Q235 carbon steel material production tank; barrel, head, bulkhead thickness of 5mm, 6mm, 5mm; spinning head; through the warehouse; bulkhead * 2; tank top stainless steel or carbon steel tank mouth * 2; stainless steel Vacuum valve*1; DN100 stainless steel or carbon steel tee pipe*1; DN100 stainless steel or carbon steel submarine valve*1; submarine valve alarm device; left and right self-flowing DN80 stainless steel or carbon steel ball valves at the rear end*2; aluminium alloy movable guardrail; rear ladder, tool box, rear bumper, side protection are all steel parts; plastic export box*2; tank shot blasting; tank inspection report; quality assurance certificate; Standard configuration of top loading (steel liner plastic): conform to GB18564.1-2019 standard; L4BH design code; positive round steel and plastic tank; Q235 carbon steel + PE liner plastic; polyethylene material liner plastic; liner plastic thickness of 16mm; carbon steel tank; rotary closure head; through the silo; double-layer bulkhead *2; top full plastic tank mouth *2; stainless steel vacuum valve *1; DN100 steel liner plastic tee pipe *1; DN100 stainless steel PTFE submarine valve *1; submarine valve alarm device; rear tail left and right self-flowing DN80 PTFE ball valves *2; aluminium alloy movable guardrail; rear ladder, tool box, rear bumper, side protection are all steel parts; plastic export box *2; tank shot blasting; tank inspection report; quality assurance certificate; Upper optional configuration: optional shape according to the announcement; steel-plastic tank mouth; safety valve; rupture disc; divided into multiple compartments; plastic lining thickness of 18mm-20mm; aluminium alloy accessories; liquid level meter; motor chemical pump or truck-mounted chemical pump; body and tank paint colour; |