Sales Executive Yanis:

Tel:+8613872882788 E-mail:[email protected]

Name of vehicle |

Chemical tank semi-trailer |

Vehicle type |

CL9402GFW301 |

Chassis type |

|

Volume |

28-35 cubic meters |

Total mass |

40000Kg |

Quality of equipment (Kg) |

9000Kg |

Vehicle length |

11000 ×2550×3900 |

Rated load mass (kg) |

21100,21165 |

The engine |

|

Chassis configuration |

Travelling configuration: complying with GB18564.1-2019 standard; L4BH design code; Fuhua 10-ton axle*3; disc brake*6; brake disc wear alarm; air suspension; Kemi EBS; steel wheels*12; Linglong 12R22.5 12PR tyres*12; Fuhua 28-ton linkage outriggers; 50 traction pins; Options: BPW axles; drum brakes; mechanical suspension; Wilburco EBS; Knorr-Bremse EBS; aluminium alloy wheels; steel wire tyres or vacuum tyres, 90 towing pins; |

tanker configuration |

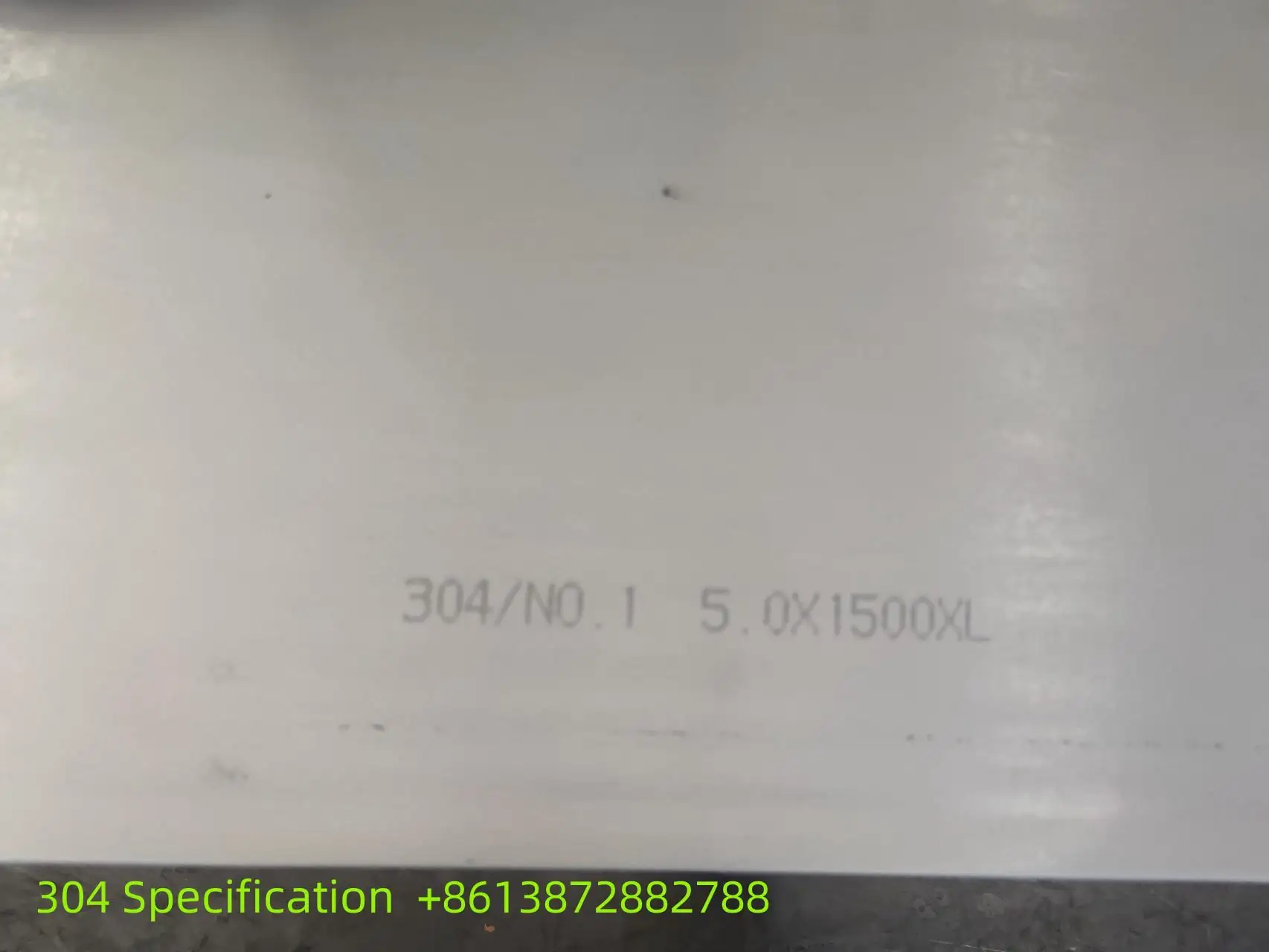

Upper standard configuration (steel liner plastic): in line with GB18564.1-2019 standard; L4BH design code; positive round steel and plastic tank; Q235 carbon steel + PE liner plastic; polyethylene material liner plastic; liner plastic thickness of 16mm; carbon steel tank; rotary closure; through the warehouse; double-layer bulkheads *3; top full plastic tank mouth *2; stainless steel vacuum valve *1; DN100 steel liner plastic tee pipe *1; DN100 stainless steel PTFE submarine valve *1; submarine valve alarm device; rear tail left and right self-flowing DN80 PTFE ball valves *2; aluminium alloy movable guardrail; rear ladder, tool box, rear bumper, side protection are all steel parts; plastic export box *2; tank shot blasting; tank inspection report; quality assurance certificate; Upper standard configuration (stainless steel, carbon steel): in line with GB18564.1-2019 standard; L4BH design code; positive round tank; SUS304, SUS316 or Q235 carbon steel material to make the tank; the thickness of the barrel, head, bulkhead 5mm, 6mm, 5mm; spinning head; through the silo; bulkhead * 2; tank top stainless steel or carbon steel tank mouth * 2; stainless steel Vacuum valve*1; DN100 stainless steel or carbon steel tee pipe*1; DN100 stainless steel or carbon steel submarine valve*1; submarine valve alarm device; left and right self-flowing DN80 stainless steel or carbon steel ball valves at the rear end*2; aluminium alloy movable guardrail; rear ladder, tool box, rear bumper, side protection are all steel parts; plastic export box*2; tank shot blasting; tank inspection report; quality assurance certificate; Upper optional configuration: optional shape according to the announcement; steel-plastic tank mouth; safety valve; rupture disc; divided into multiple compartments; plastic lining thickness of 18mm-20mm; liquid level meter; aluminium alloy accessories; motor chemical pump or truck-mounted chemical pump; body and tank paint colour; |